Your trusted

supplier for +130 years

We take care of the entire

production process from A to Z

Press work

with power and precision

Hydraulic and eccentric press machines with a capacity of up to 5,000 kN, equipped with tools, shape the material according to your requirements. Cutting, setting, deep drawing, punching, etc., the material is handled with extreme precision. Large runs or small volumes, perfection is our main priority.

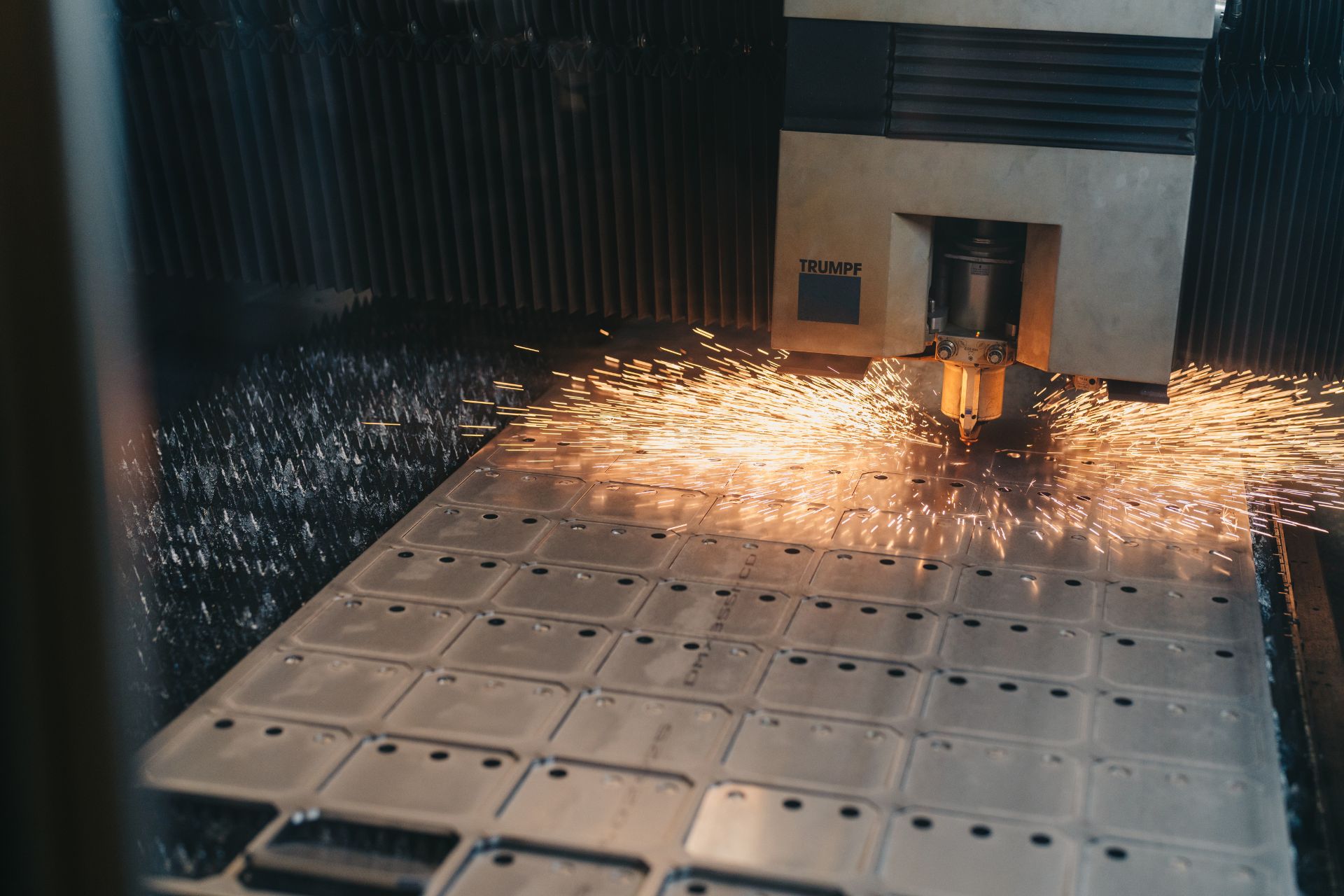

Sheet metal processing

with an eye for detail

Chamfering (folding), bending, punching, cutting, laser punch cutting, laser cutting, etc. We fashion your required product from sheet metal. The ideal means of communicating your idea to us is a 2D or 3D drawing. The execution is our responsibility. Our machinery can manufacture the most complex pieces. The more complex, the greater the challenge for our employees.

Powder coating:

Each to his own colour

We have been finishing your products with the desired colour in-house for more than 40 years. Beforehand, the products are cleaned and chrome-free passivated using an automated pre-treatment process. This is all achieved with an environmentally friendly method using rainwater and in-house treatment techniques.

Powder coating can be carried out either manually or by robot. Both methods ensure the desired colour is applied to your product. We permanently stock 500 RAL colours.

Our powder coating process has been Qualicoat Seaside certified since 2015.

Welding

We have both the know-how and skilled employees for welding single to complex assemblies. We can produce your desired construction from a sketch, design or drawing. TIG, MIG, MAG, robotic and spot welding hold no secrets for our experts. We are happy to share our knowledge and experience with you to create the perfect product.

Our team of experts

have already developed

+100,000 parts

Complex or easy, we love a challenge!

Hegge Toelevering NV is your ideal partner in production and development environments. Whether it concerns a single piece or series production, our engineering department has everything you need to bring your plans to fruition.

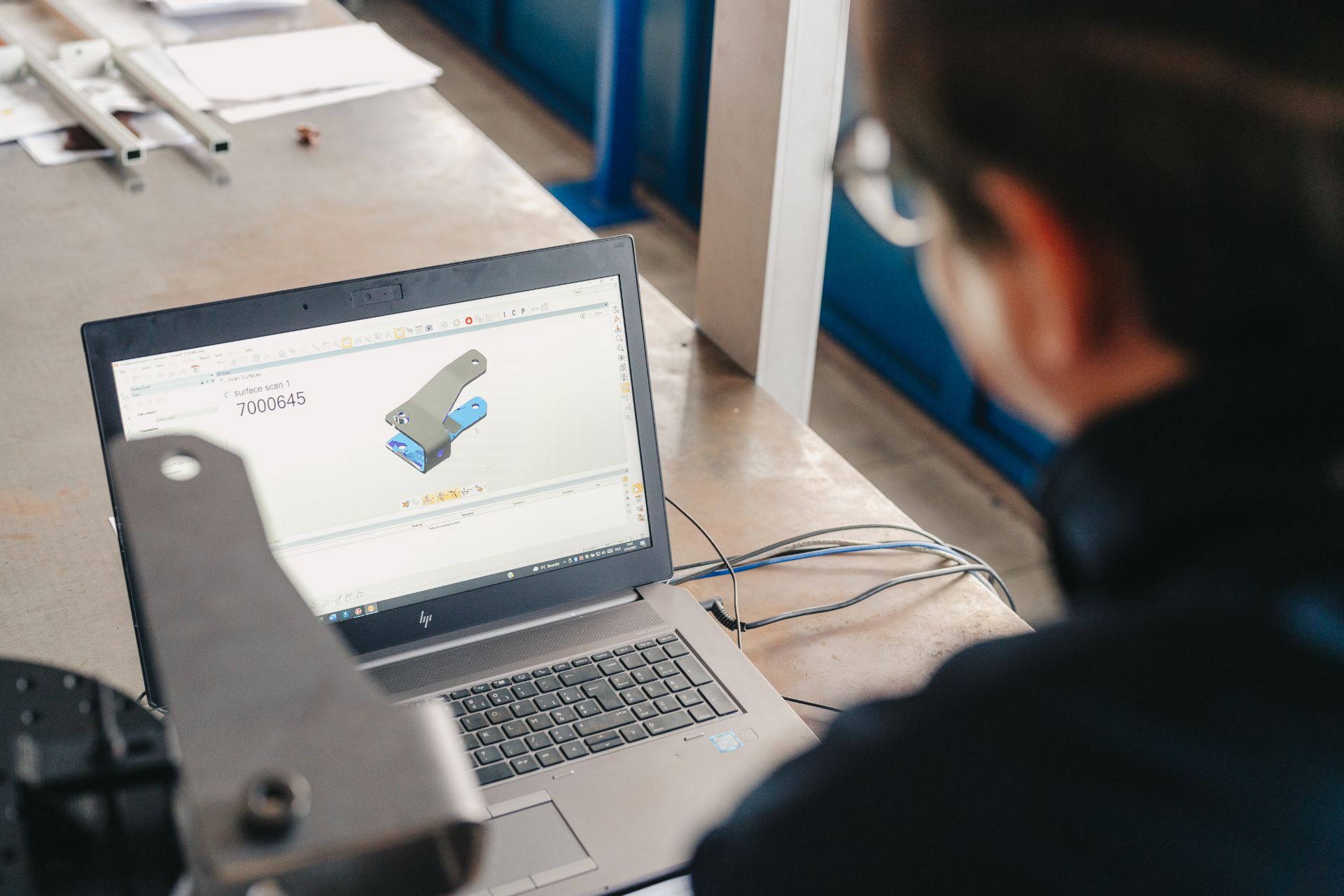

From sketch to 3D, with the right certification

Risk management and cost control are primary aspects of our production methods and development. In close cooperation with the customer, starting from a rough sketch or a complex 3D drawing, we develop products and/or production processes that meet your pre-defined requirements.

Certification according to ISO 9001:2008 and ISO/TS 16949:2009 standards ensures a guaranteed, high-quality process and provides you, the customer, with security and continuity.

Our experienced employees continuously improve our products and production processes, without compromising on talent, space or materials.

Our Hegge family

is growing

Our Handy Heggers are united by their craftsmanship, a passion for metal and a thirst for innovation, research and development. Hegge is one big family of more than 150 members, in which respect for each other, for everyone’s individuality and uniqueness, is key. Hegge is one team and we can only achieve our goals together.

Hegge Group, a Belgian family-run business

for +130 years

Since 1893, Hegge has been your reliable B2B partner for customised metal processing, façade construction for non-residential buildings and quality aluminium splash guards for trucks and trailers. A range of metalworking products, each one produced with high-quality materials and an excellent finish, that’s our trademark.

Delivery by the

agreed deadline

It regularly happens to us all: time starts to run out and lots of things take too long. Whether it’s working out projects, putting technical details down on paper or executing an on-site assembly job. Hegge Toelevering NV gives you a helping hand.

We offer you the possibility of ordering parts included in our standard production range, ready for collection within 48 hours or two working days.

48-hour service

Our extensive stock of materials is used for this quick service. Steel, stainless steel and aluminium can be laser-cut, punched, cut, chamfered (folded) and welded and, if required, powder coated.

It goes without saying that we apply certain guidelines to guarantee this service. You can consult them here. A list of the available colours can be found here.

If you have any questions or want more info, feel free to send an e-mail to 48-uur@hegge.be.

More than 500 companies and

manufacturers already rely

on our service

What is your

idea for a product?

What does Hegge stand for?

-

Quality

Quality

At Hegge, quality is guaranteed. Thanks to our many years of national and international experience in the industry, as well as our in-depth expert knowledge, we know perfectly well how to create a sound product that meets all your needs. You can count on our professional, efficient and friendly approach at all times.

-

Flexibility

Flexibility

Our aim is to optimally unburden you, so we are always as flexible as possible. We take a solution-oriented approach and effortlessly adapt to the specific requirements of your project. We distinguish ourselves through our versatility and enthusiasm.

-

Innovation

Innovation

Every day, we consciously strive to improve ourselves, our internal processes and our products. We are always on the lookout for innovative angles and closely monitor developments in the industry, to deliver the best end results time and time again.

-

Commitment

Commitment

Whatever your personal project entails, at Hegge our commitment is plain to see. We jointly reflect with you on your plans, needs and requirements. After all, this is the only way we can deliver a product that satisfies you 100%, and that’s our ultimate objective.

-

Sustainability

Sustainability

In our processes we are extremely mindful of sustainability and ecologically responsible choices. But sustainability and mutual trust are also vitally important in our relationships with employees, shareholders and customers. We are your long-term, reliable partner.

-

High-quality finish

High-quality finish

Because we want the absolute best for our customers, we exclusively offer products with a high-quality finish. That’s our guarantee to you. What’s more, we use only first-class, durable materials, which you can trust implicitly.

How can we help you?

Hegge Toelevering nv

Bosstraat 137

B-3930 Hamont-Achel

+32 11 66 06 20

toelevering@hegge.be

BE 0433.921.382